No polymerization

No gelation kinetics, curing time, or setting artifacts.

The BioECMCode™ Structural ECM Platform

Most extracellular matrix systems rely on soluble proteins, bulk gels, surface coatings, or reactive polymer systems that require user-controlled preparation. These approaches introduce experimental variability through:

As a result, experimental outcomes often reflect ECM preparation variability rather than true biological differences.

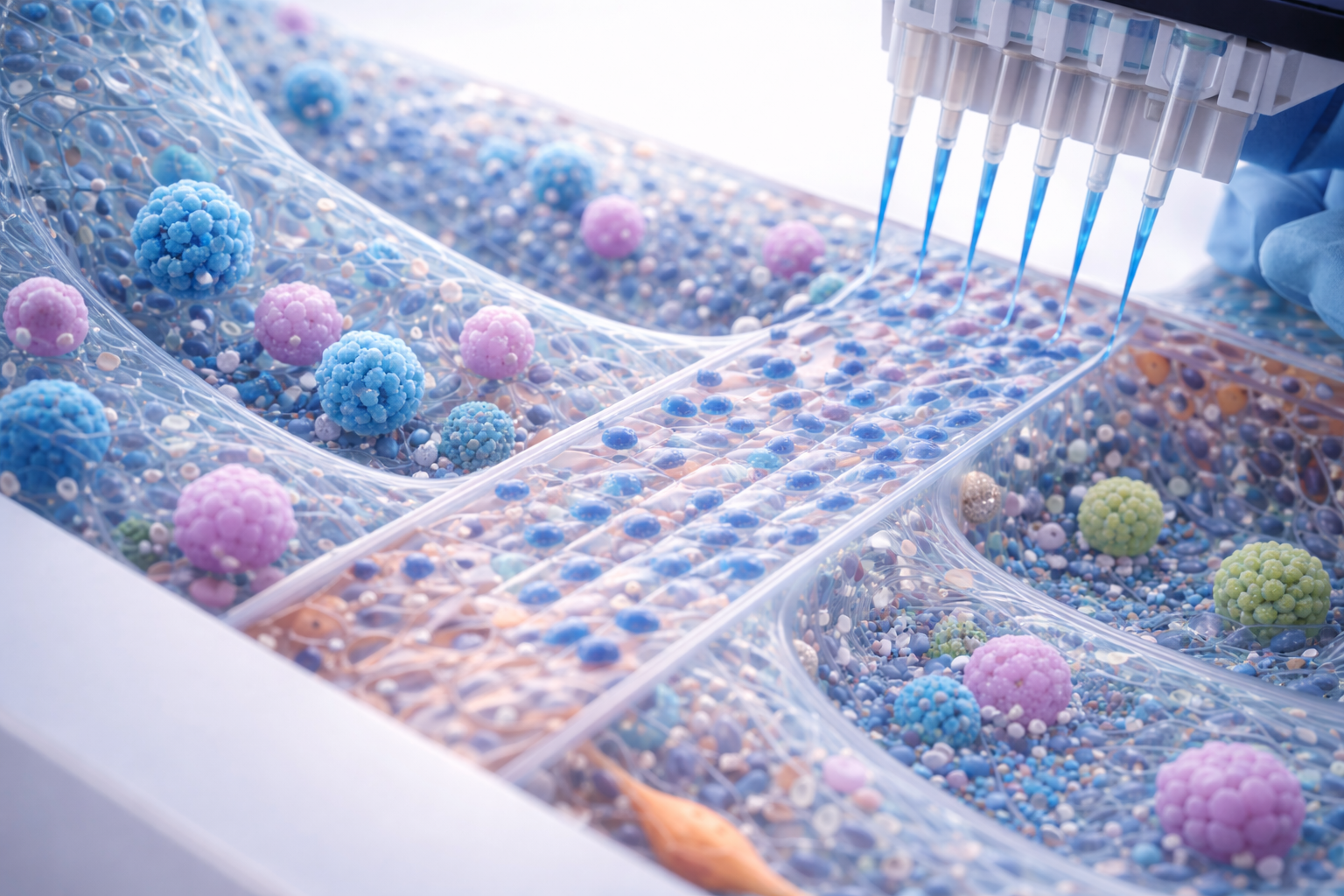

BioECMCode™ replaces formulation-based ECM systems with structurally encoded extracellular cultureware. Our products are:

Cells interact with a fixed extracellular architecture that is consistent across lots, experiments, and laboratories, and independent of user handling or timing.

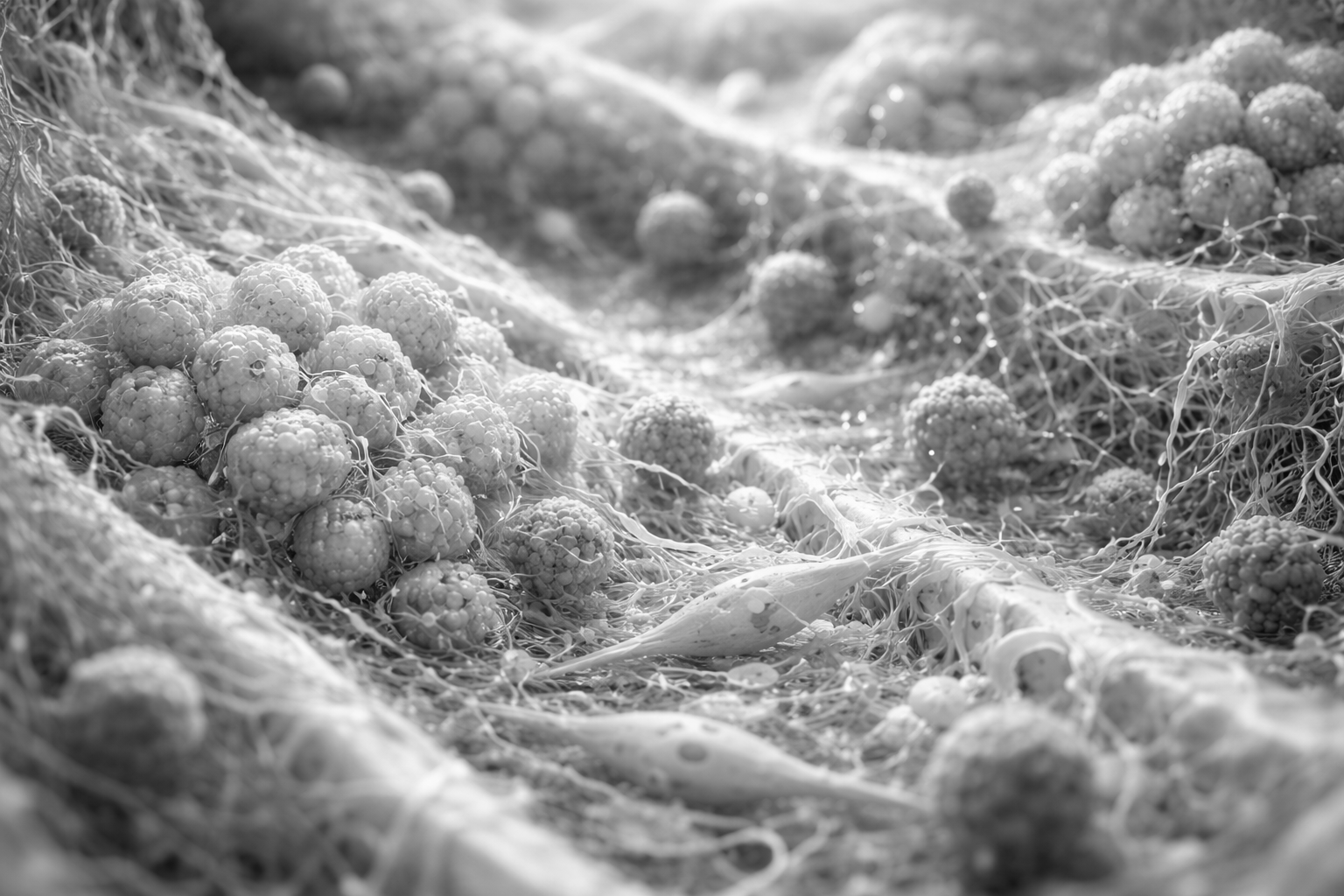

Instead of tuning extracellular behavior through chemistry, concentration, or polymerization, BioECMCode™ encodes extracellular instruction through physical architecture, including:

This enables reproducible cell–environment interactions driven by structure rather than formulation.

BioECMCode™ products require no polymerization, no crosslinking agents, and no formulation steps.

No gelation kinetics, curing time, or setting artifacts.

No stiffness tuning or formulation-dependent workflows.

No crosslinkers, ligand conjugation, or chemical coupling.

Structure-driven ECM control that simplifies workflows and improves reproducibility.

Minimize operator-dependent and preparation-related variation across experiments.

Ready-to-use formats that reduce handling complexity and setup time.

Consistent extracellular architecture across lots, laboratories, imaging, and automation.

Talk to our team for customized support